Intergranular embrittlement is one of the most dangerous effects responsible for the catastrophic failure of construction metallic materials. The reason is that it proceeds very quickly and its occurrence is hardly predictable. However, it is known that this problem is closely connected to the chemical composition of intergranular regions – grain boundaries. Solutes and impurities tend to accumulate – segregate – at grain boundaries at enhanced temperatures in such an extent that they can occupy all available atomic positions there.

As a consequence, the bonds at the grain boundaries change so that a significant reduction of material cohesion can occur resulting in flash break of the part under loading. This was practically observed e.g. in the case of the destruction of the rotor turbines in nuclear power stations in the UK in the 1960s.

Systematic experimental, as well as a theoretical research of the specialists from the Institute of Physics of the Czech Academy of Sciences (CAS), the Institute of Physics of Materials CAS, and the Masaryk University in the field of grain boundary segregation in metallic materials and its consequences for intergranular embrittlement, brought original fundamental knowledge. The examples of their outputs are anisotropy of grain boundary segregation, construction of the grain boundary segregation diagrams or so-called enthalpy–entropy compensation effect, and introduction of the term „segregation volume“. No wonder, that the summary of the values of the energy of the grain boundary and/or surface segregation for wide spectrum of solutes in iron, nickel and aluminum, and of the values of the strengthening/embrittling energy, both obtained by own experiments and calculations and taken from the literature, compiled by these scientists, was published in the top journal in the field of materials, Progress in Materials Science, possessing the impact factor of 31.083. The value of this success is enhanced by the fact that the team succeeded in doing that without any external reputable scientist from a prestigious western institution “opening the door” into such a journal: the published paper originates exclusively from Czech authors.

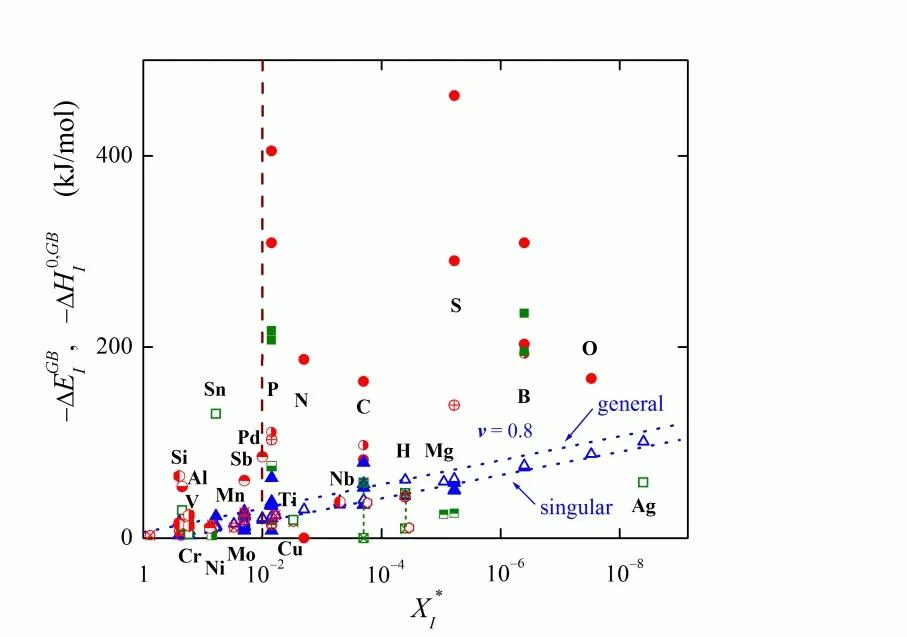

Besides the review of calculated and measured segregation characteristics, the paper also provides generalization and critical evaluation of the credibility of numerous data appearing in the literature. The authors show, for example, that the values of the segregation energy determined experimentally (blue triangles in Figs. (A,B)) and those calculated theoretically (red and green symbols in Figs. (A,B)) exhibit excellent agreement for solutes with good solid solubility in the host metal (more than 1 atomic %) whereas a large scatter for solutes with lower solid solubility was found. The reason for this change in comparison of these two types of the data is that the calculations are most frequently performed using the cells containing about 100 atoms or less so that the solute concentrations are of about 1% or more. Therefore, for solutes with the solid solubility lower than 1 %, the calculated values of grain boundary segregation energy correspond to a non-equilibrium state and thus they are hardly comparable to experimental results obtained at equilibrium conditions. On the other hand, the problem of the solid solubility disappears in the case of the strengthening/embrittling energy as the controversial non-equilibrium term is subtracted during calculations.

The results of the paper may be used not only for a critical approach to the values of the segregation energy obtained experimentally as well as calculated theoretically but also for a qualified estimate of both the chemical composition of individual grain boundaries or free surfaces and the effect of individual solutes on intergranular cohesion in construction materials based on iron (Fig. (C)), nickel and aluminum. A similar approach may be applied to any other host material.

P. Lejček, M. Šob, V. Paidar: Interfacial segregation and grain boundary embrittlement: An overview and critical assessment of experimental data and calculated results. Progress in Materials Science 87 (2017) 83–139. http://dx.doi.org/10.1016/j.pmatsci.2016.11.001